Technoton Engineering team releases one more industrial product for his client this week. The target was to develop from scetch to serial production an automatic calibration station for fuel tanks. This project included mechanical engineering, PCB design and Android App development. The key role in calibration station development was given to a project manager. It was up to him to choose right components to meet technical specification and final product price.

Where there any difficulties met managing this project?

" Automatic calibration station is developed for fuel tank calibration. It saves up to 50% of time while installing level or volume sensors and increases measurement accuracy. There were always 3 things in my mind for which I felt worried most of time.

1) Station should be portable.

2) Flow rate should be high to save time during the calibration process.

3) Prevent diesel foam appearance to increase automatic measurement accuracy.

Today, our project has passed all tests and is ready for serial production. "

Nikalai Yanel

PM at Technoton Engineering

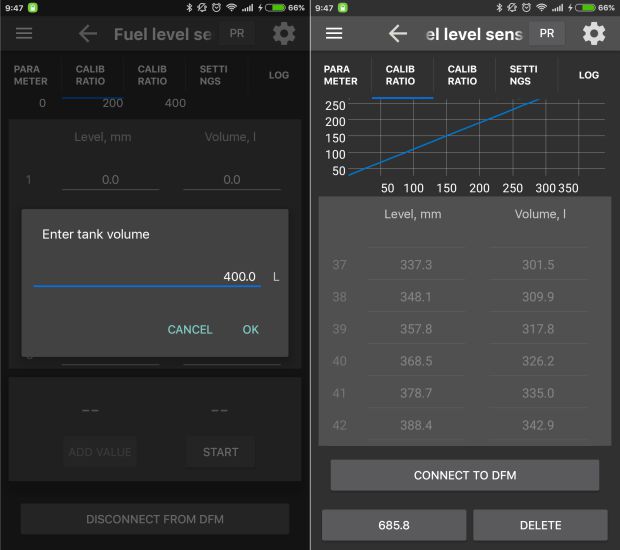

The system of automatic calibration table filling is realized in the calibration station development project. The automatic station generates up to 60 calibration points of a smart sensor. With this station installation engineer job is just to monitor the whole process and to save final results. The calibration process is managed over a tablet or a smartphone with Android OS. The user-friendly application shows the whole calibration process with flow rate values and calibration table.

Do you need any technological equipment? We may do it! Contact us for free engineering advice.