We design hardwaredevelop softwaresolve integration tasks for CAN bus tools.

Technoton Engineering does custom CAN bus tools development. We develop CAN bus hardware and CAN bus monitoring tools, solve j1939 interface and integration tasks.

CAN bus solutions Design & Development

The CAN bus is a reliable, economic and robust interface that`s used for real-time communication. Technoton Engineering has achieved exclusive skills over the years of researching in the CAN bus tools development space. Today, we offer customization services of ready to market products as well as advanced systems integration.

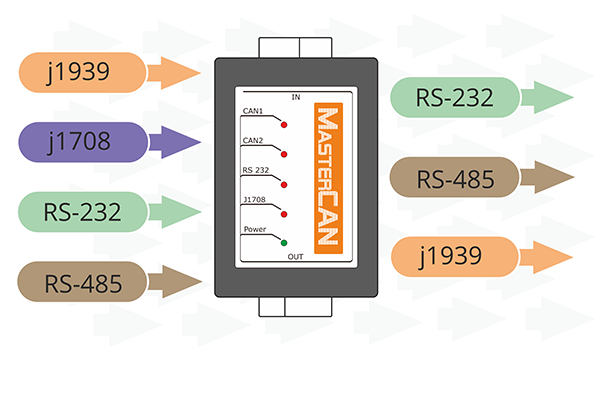

If you design a CAN bus system, we can help to develop a compatible CAN bus product to ensure reliability and exclusivity for your solution. Among popular task that we solve there are CAN bus interface gateways, CAN bus readers, analog to CAN bus J1939 converters, digital to analog converters, IoT gateways and etc.

CAN bus tools development for your smart system in partnership with us will obtain advantages of using our expertise:

- 20+ CAN bus hardware design projects have already been completed and put into production

- Experience in CAN bus design for vehicles, assets monitoring systems, industrial automation

- CAN bus sniffer, CAN analyzer, CAN imitator, CAN bus decoder along with CAN bus monitoring software are created by our team

- J1939, J1708, NMEA 2000 protocols support

- 10`000+ CAN parameters database including J1939, ISO BUS

Our foundation is to solve challenges.

CAN bus reader with a unique design required by your system

CAN bus hardware design

Self-diagnostics, preprocessing, analytics and other functions in your CAN device

Interface converter (CAN-RS485-Analog) with special requirements

CAN bus to IoT gateway

Full CAN bus integration to your new electronic device meeting fast time to market terms

and more...

Manufacturing

We offer our clients a comprehensive put into manufacturing service for their electronic products. We assume responsibility for the production of your product, from material procurement and logistics through to device assembly, sales packaging and automated labelling of your equipment and systems.

Our advantages for CAN tools development

- CAN bus hardware portfolio. Our customers benefit from reliable products as well as lifetime access to functional and hardware upgrades.

- Fast development time for off-the-shelf product. CAN bus in-house expert team makes CAN bus design thoroughly, thinking ahead about product functionality, usability and future manufacturing launch.

- Desktop configuration software. All firmwares are configurable for a final application, so no a programer is required at integration stage.

- Cost-effective customization. There is no matter your size, we use our time-tested solutions as a base and achieve reliability from a 1st prototype.

REFERENCE PORTFOLIO OF CAN BUS TOOLS PROJECTS

CAN data converters

CAN DAC J1939 i/o module

CAN bus analyzer-simulator

CAN BUS HARDWARE DESIGN ON THE READY PLATFORM

Take a look at the following selected hardware & software customized solutions of CAN bus tools, that can be used as a foundation for your product:

J1939 to MQTT Gateway is an original electronic device that allows fleet management solution providers, developers, and system integrators to collect telemetry data from CAN bus. All useful telematics data may be collected into a configurable report and transmitted to a cloud via MQTT communication protocol.

CAN bus Displays that we design are targeted to CAN data monitoring and include self-diagnostics together with a high-security level. The hardware of displays is for industrial, agricultural, automotive and marine applications where there are standards to components, vibrations, temperature, humidity, voltage supply and etc.

An advanced solution for use in automation systems, networks consisting of analog and digital sensors, control units, communication modules. Being a valuable part of the modular architecture and edge computing, the smart interface converter solves a problem of step by step digitalization of conservative analog technologies.