Our Smart Meter Platform opens new opportunities for a smart flow meter and IoT flow meter development. Since 2000 Technoton Engineering develops smart flow meters and today the company offers a ready-to-use library of modules for tailored flow meter development with a modular architecture and wide customization opportunities.

With hardware & software ready modules of Smart Meter Platform it`s possible to develop an IoT meter from a sketch or to upgrade any classical meter. Upgrading classical meters, you open new opportunities and catch free market fractions. Among popular new meter types which we develop there is a NB-IoT smart meter, IoT smart flow meter, BLE smart meter, CAN bus flow meter (J1939).

A primary transducer together with our customized integrated electronics will reach goals of complete product development in 0 – 3 months and rapid mass flow meter production launch. A customized intelligent electronic module is integrated into a classical flowmeter to get new functionality and connectivity like NB-IoT, Bluetooth (BLE). This approach is used for stand-alone applications and also for IoT meters working in measuring, diagnostics and telematics IoT systems with tailored requirements to output interfaces, secondary data conversion, measuring accuracy, flow meter reliability.

Learn more about Smart, IoT meter development

What can IoT smart meter built on Smart Meter Platform do?

IoT smart meter becomes a time-tested innovative IoT meter that sends preprocessed raw data to resource suppliers (IoT smart metering). Moreover, all IoT smart meters have a real-time reaction on configured events and can notify a customer by a SMS or an e-mail. LTE NB-IoT with smart metering technology makes it possible to do stand-alone smart meter development without a need to change a battery for years. Extra security levels are realized by password on access settings and by TLS protection during data transmission.

Features of smart meter

- Build-in data reliability ensuring system (self-diagnostics, settings and counters authorization access, identification and registration of tampering attempts)

- Secondary signal conversion (linearization, filtration, thermal correction)

- Operation modes define (separate meters for different modes, events detection)

- Wired network with digital data transmission, data sending to an IoT platform

- Automation of technological processes (group configuration, calibration, verification)

Time-tested hardware & software solution is used to replace mechanical counting devices of any liquid and gas flow meters, to create new flow meter types or to replace outdated technology for transmitting information about the flow to pulse and current loop interfaces.

The electronic smart meter module receives signals from a measuring chamber, performs filtering and validation of data, pre-tuned data processing by built-in algorithms, accumulation. Data is presented on the display or in a local interface or sent to a cloud or user directly.

Designed on IoT Burger™

- Reducing the requirements for server applications + saving on the development of analytical software

- Ability to completely refuse from server software

- Definite data interpretation (firmware, server representation, documentation)

- Rapid functionality build-up for special requests

- Build-in data reliability ensuring system

- Adapted and tested for work in automotive, industrial, marine applications

- The ability to build a model line on a single hardware platform due to flexible settings

- New connectivity opportunities - NB-IoT smart meter, IoT smart flow meter, BLE flow meter, Wireless smart meter, BLE smart meter, CAN bus flow meter (J1939)

REFERENCE PORTFOLIO OF IoT FLOW METERS

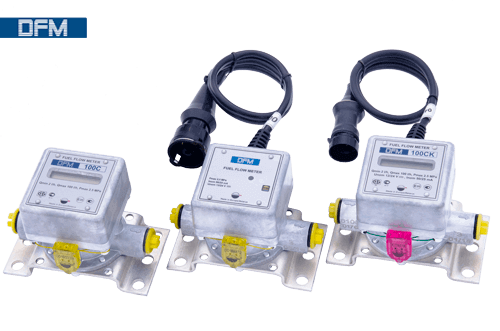

Smart IoT fuel flow meter product line

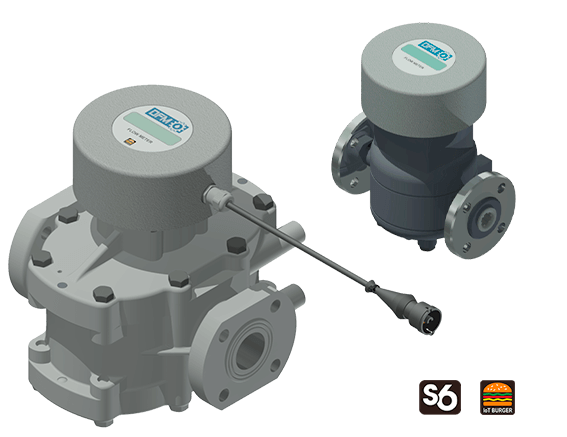

Industrial IoT flow meter

Smart IoT flow meter development results include detailed design documentation, a user manual template, desktop software for configuration and status control.

Developed to be compatible with S6 technology: any peripheral devices that have an interface S6 (other flowmeters, level sensors, telematics gateways and etc.) can be connected.

A contract for a flow meter development is usually accompanied with the following services, depending on the client's needs:

- flow meter enclosure development

- mechanical engineering

- hardware customization (adding interfaces, changing the power supply, selection of a communication module)

- adapting the embedded software

- making samples

- running verification tests