How To Design And Optimize Your Connected Product To Get The Best Battery Life

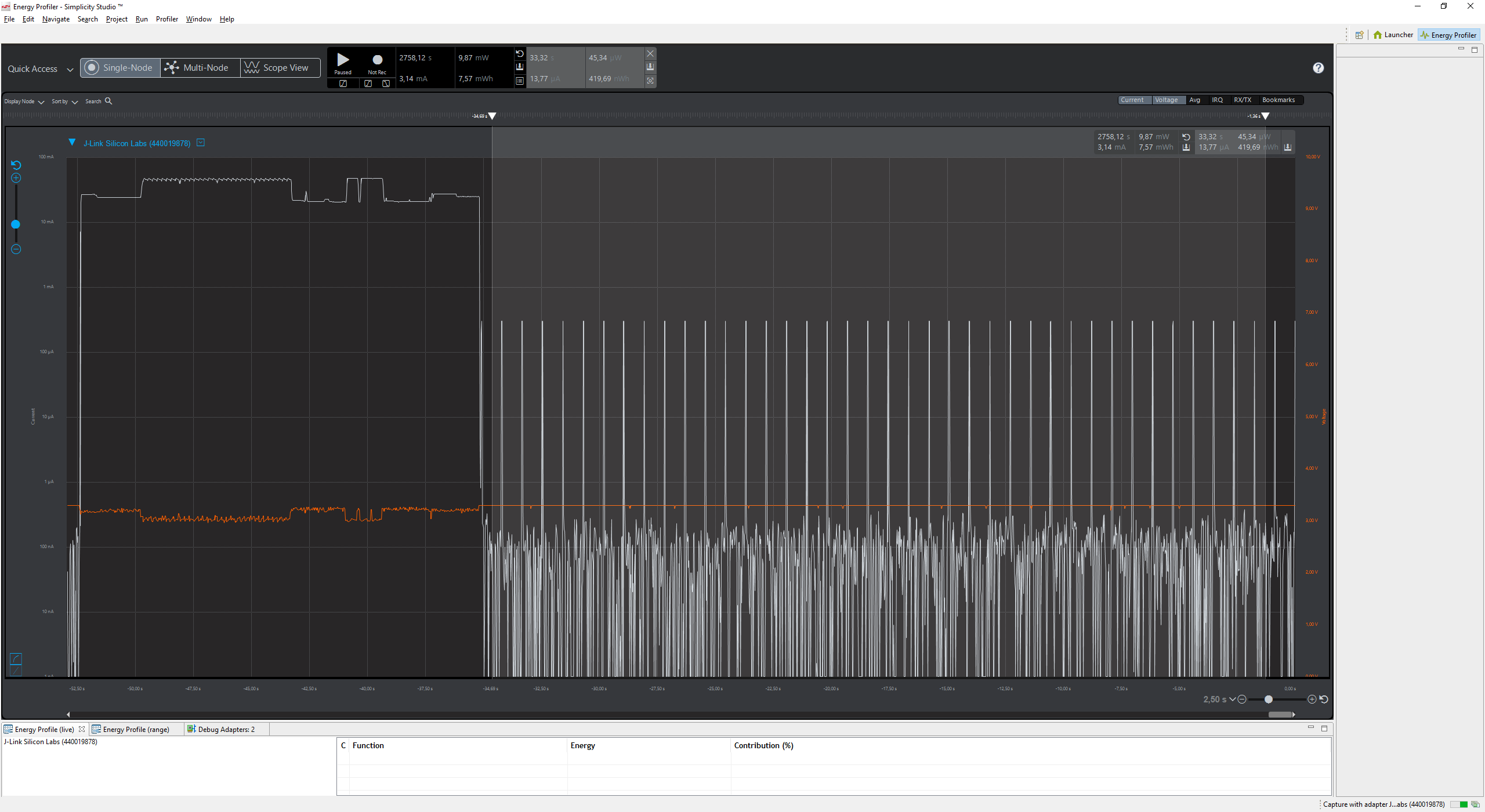

Technoton Engineering best practices are perfect at delivering connectivity and long-time battery life for devices. A well-designed sensor in deep sleep typically draws just 0.3-4.5µA. On working mode with connection to a wireless network, a device draws about 50-80mA on average. If you’re going to develop a stand-alone hardware that will be battery-powered, the way to start is to think about the full application algorithms of your device.

How To Make Your Device Avoid Wasting Energy?

It`s completely the same when you switch off the light when you leave a room, a design of a battery powered hardware needs to be considered for wasted energy.

- Choose low current consumption components at zero-load mode. Power consumption at zero-load mode is the current a component draws only to keep itself. For instance, a DC-DC regulator is to hold a 500mA load, but it still can draw at zero-load 10-20µA current.

- In solutions where battery life is important, a power supply switcher is the best choice for efficiency, sleep-mode and supply current consumption.

- Take into primary priority components with enable pins or low-current sleep modes. It’s very effective to be able to power-down entire blocks of the hardware that are not necessary, especially for devices which use different components at different time.

Get All Available Power From Your Battery

Batteries have to decrease powerful capability whilst discharged at a high rate. To assist lessen the draw at the battery and maximize battery life, place a capacitor in parallel with the battery to lessen immediately draw and powerful output impedance.

Choose A Right Battery

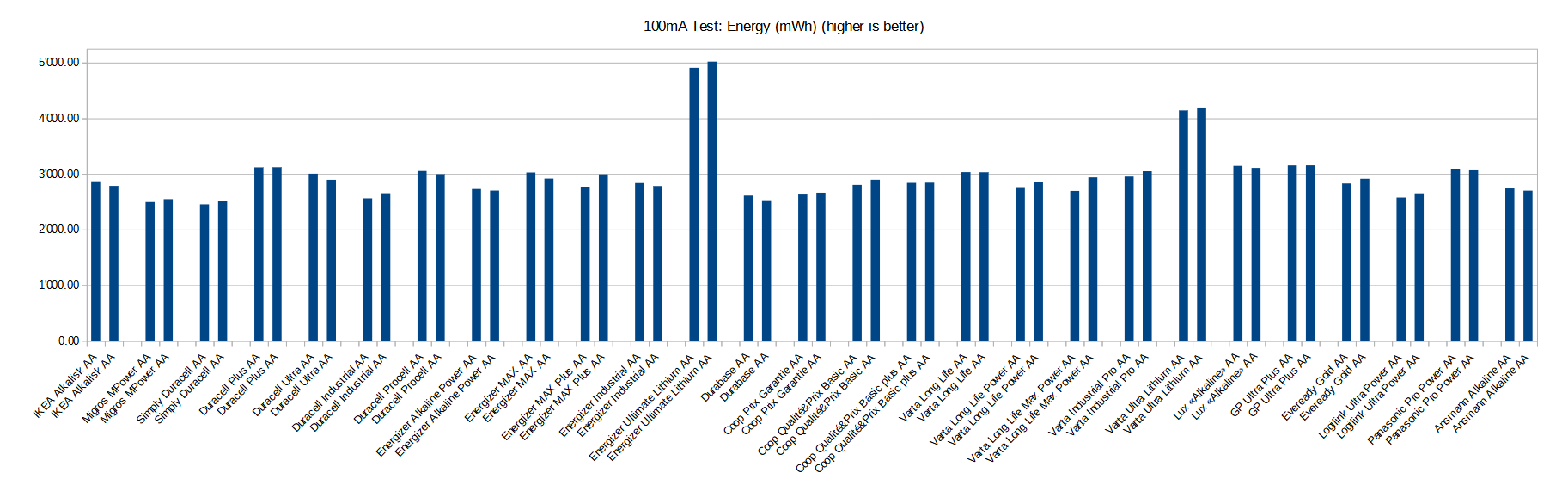

After doing a market analysis of power supplies, as well as technical analysis and practical reports and studies of power supplies, we came to the conclusion that household power supplies well-advertised and often recommended for use are not suitable for use in battery powered devices. These are mainly common disposable salt, alkaline and lithium chemical power supplies, which are easily recycled, so they are sold in bulk. The same applies to lithium-ion batteries, which are also designed to the detriment of their characteristics, only to make them easy to dispose of, let`s not focus on this.

There is a market for industrial power supplies with complex formulas, certified and recommended for special applications. For example, power supplies are recommended for medicine, industry, and professional equipment. This is confirmed by various independent experts who have tested these power supplies, professional users and manufacturers of professional equipment. Manufacturers of medical equipment and industrial equipment for which the use of the following power supplies is recommended. This is also indirectly confirmed by tender purchases of state-owned enterprises, medical institutions and industrial large business structures.

Take into account a chemical power supply based on LiFeS2 (Lithium-Iron).

After analyzing LiFeS2 power supplies, the market leader is EVE Energy with FR3 AAA , 1.5V 1.1Ah batteries, FR03EVE product series suitable for most industrial applications.

For example, a AA lithium (LiFeS2) battery has a very flat discharge curve and will hold approximately 1.5V as it discharges. This battery is rated at 3000mAh.

Optimize Embedded Software For Best Performance

- Control the RGB LED using PWM. Reduce the pulse width by half or less, the glow will be the same, but the consumption is less, reduce the duration of the indication.

- Reduce the amount of transmitted information - the number of transmitted bytes. The date and time of the measurement do not exactly need to be transmitted, because this can be determined from the arrival time of the data packet if the data transmission occurs after the measurement. The less transmitted data, the less the transmitter works, the less energy is consumed.

- Consistently power-on the necessary modules and not all at once. For instance, first turn on the measuring sensor, measure it, turn it off, then turn on the power of the accelerometer, measure the angles, turn it off. Then sequentially turn on the communication module, try to transmit, turn it off.

- Check and disable unnecessary peripherals and ports. Before preparing to sleep, turn off all peripherals except those needed to wake up. All unnecessary ports must be in high impedance or Z-state during sleep mode. This ensures that there will be no current leakage through the ports anywhere. Also, disconnect from the power completely unnecessary peripherals programmatically and physically. At MCU may be an internal converter for the LCD display and unused ports and interfaces that can simply be enabled by default. It is necessary to disable them programmatically if they are not used and also physically disable them by power in the circuit.

Conclusion

As we`ve seen above, the implementation of all tweaks can rise the life of a battery powered device dramatically.

Our latest optimization project result is that we`ve managed to rise a stand-alone sensor life on a single AAA battery from 2 months to 10 months. We`ve managed to reach such results thanks to making some PCB changes and with the integration of the power management module inside embedded software.

The expertise of Technoton Engineering DEV team in the area of battery powered hardware is development from zero stage and optimization of existing devices for power consumption and connectivity.

You are welcome to get in touch with us by leaving a request.